MetTec

Specialized companies in the field of injection technologies for steel plant optimizing solutions.

Specialized companies in the field of injection technologies for steel plant optimizing solutions.

Our long time cooperation and subsequent combination of injection systems for solid and gaseous matters have resulted in the development of superior tools for the steel producing industry.

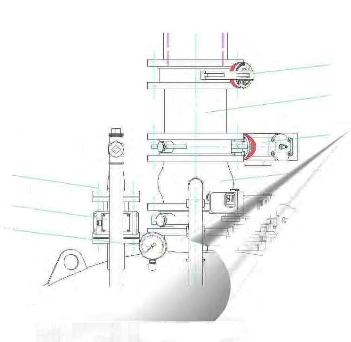

The unique combination of pneumatic based conveying and injection systems combined with innovative new system of fixed installed water-cooled lances for gaseous and solid finest materials, offers our clients a total package for all injection matters from one source.

The absolute concentration on optimized solutions in relationship to cost and efficiency has gained us a strong name in the industry and the number of satisfied customers is steadily growing. Our constant research in close co-operation with the industry based on the requirements and needs has been the foundation for many developments of innovative new process technologies. The extensive knowledge gained and results achieved are introduced in all offered equipment and does reflect our commitment to a close customer relationship. Injection systems for:

- Active Chemical Energy and Multi Injection (ACE & MPi)

- KME/ CUPRUM: Casting Technology solutions: Complete new Casters, Copper Mould Tubes Billets, Rounds, Beam Blanks, Caster Revamp

- Mould Profile Measurement Systems : Highly accurate and precise with history.

- High Current Systems : Copper/Al Electrode Arms, Copper delta, Electrode Holders, Water Cooled Cables, Copper Contact plates,Flexible Copper Busbars, Copper Busducts.

- Manufacturing: EAFs, Laddle Cars, Laddle Furnace/Laddle Furnace Roof, Water Cooled panels, Lances/Burners

- Burners Management System, Burners for Vertical/Horizontal Preheaters

- Lance Manipulator with Oxygen, Carbon, Temperature and Sampling Lances.

- VD/VOD/AOD/Chemical Heating.

- Spares: Ceramic Lined Flexible Hoses, Elbows, Pipes, Valves, Filters.

- R & D: Geo polymer cement using EAF Slag and Fly Ash